Sustainability and the Environment

All activities and processes at PLASGEN are aligned to the principles of the circular economy, with the primary objective of sustainability.

The purpose of the circular economy is to reduce or minimise the use of raw materials and the production of wastage and residues, whilst maximising the value of products, materials and resources (water, energy…) in the circular economy for as long as possible.

Company management supports a new model of sustainability which optimises the efficient use of resources using environmental, economic and social factors as key indicators.

Our commitment to sustainability is also reflected in the development of sustainable projects in conjunction with our stakeholders: clients and suppliers, as well as public institutions and other bodies in the fields of academia or research.

Nuestro Compromiso Estratégico es el apoyo al cambio hacia una economía eficiente en el uso de los recursos, colaborando e integrando a todas las partes interesadas, solicitando información relativa a sus consumos, riesgos y modelo de gestión sostenible.

Our strategic commitment is to support change for an economy which is efficient in its use of resources, collaborating with our stakeholders by requesting information concerning their consumption levels, risks and model of sustainable management.

Our strategic commitment is to support change for an economy which is efficient in its use of resources, collaborating with our stakeholders by requesting information concerning their consumption levels, risks and model of sustainable management.

Efficient Product Design

Sustainable Solutions

100% recyclable

All our products are 100% recyclable.

ECO-Plast

We have developed the “ECO-PLAST by PLASGEN” product line, manufacturing products with a high percentage of certified post-consumer recycled material.

Blauer Engel

We have obtained Blue Angel certification.

Circular Economy

We actively collaborate with organisations which commit to the circular economy through use of recycled plastic, EuPC and ANAIP. In 2020, we attained the MORE label, a marker of our progress.

100% recyclable

All our products are 100% recyclable.

ECO-Plast

We have developed the “ECO-PLAST by PLASGEN” product line, manufacturing products with a high percentage of certified post-consumer recycled material.

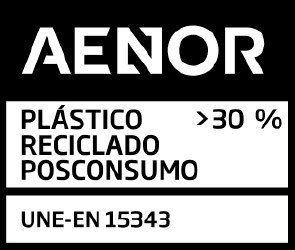

High percentage of post-consumer recycled material certified by AENOR

Circular Economy

We actively collaborate with organisations which commit to the circular economy through use of recycled plastic, EuPC and ANAIP. In 2020, we attained the MORE label, a marker of our progress.

Ecoefficient Practices

Our Commitments

We actively assess occupational risk prevention and we have a policy of continuous improvement of working conditions.

We have implemented and certified the Occupational Health and Safety Assessment Series OHS18001:2007.

In 2020Successfully passed the Occupational Health and Safety audit under ISO 45001: 2018

CurrentlyPrevention Planning and Risk Evaluation activities are at the integration stage, for reliable and effectivement management.

PLASGEN MATERIAS PLÁSTICAS S.L, is enrolled in the Equal Opportunities Plan (Code 41112512112023), with effect from 19-05-2023 to 18-05-2027, through the REGCON ECONÓMICO platform.

– We reduced our C02 emissions by 5.5% (-78,300 kg), following the conversion of our entire fleet of forklifts from diesel to electric. – We achieved a 2% reduction in our water consumption. – We managed and recycled more than 100,000kg of plastic waste, returning the excess to the value chain to be processed once more into the final product. – We replaced traditional lighting across our installations with latest generation LED lighting and motion sensors, reducing our CO2 emissions by 2%.

Since 2018– We ensure that at least 50% of our electricity is generated from renewable sources. – We efficiently adapt our productive technology for minimal CO2 emissions and zero industrial waste, our fundamental principle being the reuse of surplus produce and minimising the use of natural resources. – Efficient purchasing – We consider environmental aspects for all purchases of machinery, raw materials, packaging, etc, with the objective of minimising any associated environmental impact. – We operate an efficient paperless policy. It is estimated that 24 trees are cut down for each tonne of paper. Implementing an e-billing system is more than a simple gesture to the environment. According to a study by the SERES Foundation, every million invoices printed implies the use of 10 tonnes of wood. The paper industry is one of the highest generators of air and water contaminants, as well as gases which cause climate change. We ensure that the little paper we use is 100% recycled and certified. – Our commitment to the environment is reaffirmed with the implementation and certification of the environmental management system ISO 14001:2015.

Since 2020 We have been working on a C02 plan reduction plan.Granting our staff the opportunity to do their part to improve the environment, reducing the CO2 generated by their vehicles.

In this way, we encourage our staff to come to work by bicycle, rewarding their efforts with financial incentives.

For PLASGEN

We manufacture products using fewer materials, water, energy, etc, generating less waste which needs to be properly managed. We adapt our production processes, standardising designs and production techniques, enabling us to reduce our consumption of raw materials for each application we manufacture, thereby minimising our environmental footprint.

For our clients

Our clients buy a more long-lasting product, which requires less energy or consumables to work and can be easily adapted. We provide our clients with technical advice on products and materials to achieve a reduction in film thickness, resulting in a notable reduction in consumption.

For our society

Society benefits from a greater availability of resources which can be used for other products and services. Due to the reduced environmental impact, there is a saving on treatment and restoration costs.

Quality

OUR CERTIFICATIONS

- +34 955 90 10 65

- comercial@plasgen.es

-

Pol. Ind. El Mirador, 11.

41400 Écija (Sevilla) Spain

Apartado de Correos, 337